No other protective coating for steel provides the long life durability and predictable performance of hot dip galvanizing:

THA’S WHY THOSE IN THE KNOW – HOT DIP!

BENEFITS:

Competitive first cost: For many applications, the first cost is lower than alternative coatings

Long Life: Often exceeding 30 years

Lowest Lifetime cost: Low initial cost and long life make galvanizing the most versatile, economical method of protecting steel

Reliability: Specified at AS/NZS 4680 and equivalent World Standards

Speed of application: A fully protective coating can be applied in minutes

Complete Coverage: All exposed steelwork is completely coated both internally and externally

Ease of inspection: The nature of the process is such that if the coating looks continuous and sounds it is so

Coating toughness: Alloy layers are harder than the steel on which the coating is formed.

Adhesion: Metallurgically bonded to steel ( basically means the metal reaction joins the zinc and steel together making it stronger) painting doesn’t do that.

Coating thickness: Galvanized coatings are distinctly thicker at corners and edges, an important advantage over most organic coatings which thin out in these critical areas

Cathodic protection: Electrochemical protection of damaged areas

Faster construction: An off-site finish, geared to fast-track construction. Requires no -site repairs other than weld damage

Top Coats: Top coats can provide – Colour | Chemical resistance | synergistically – extended life

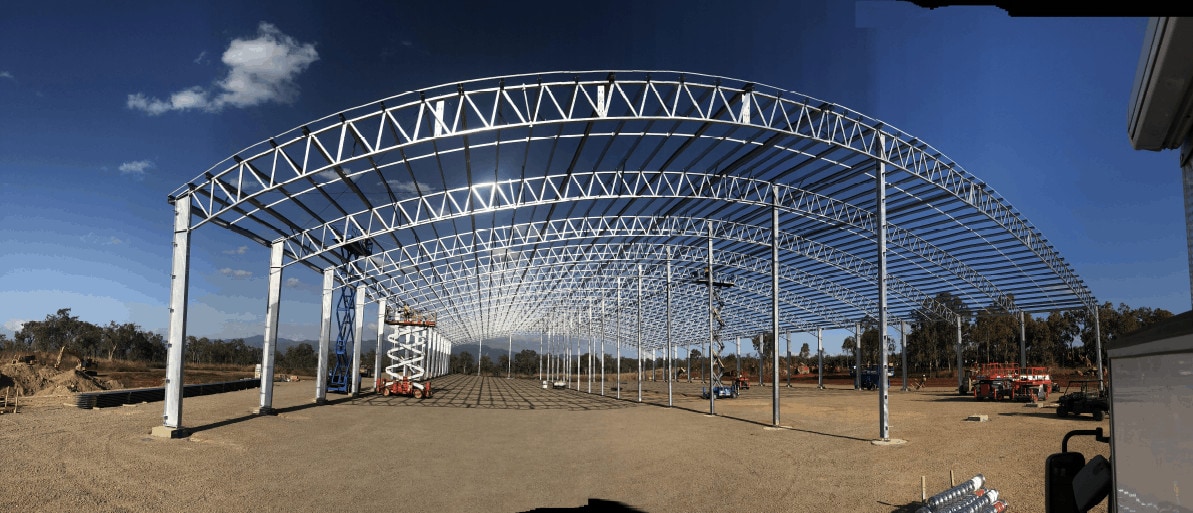

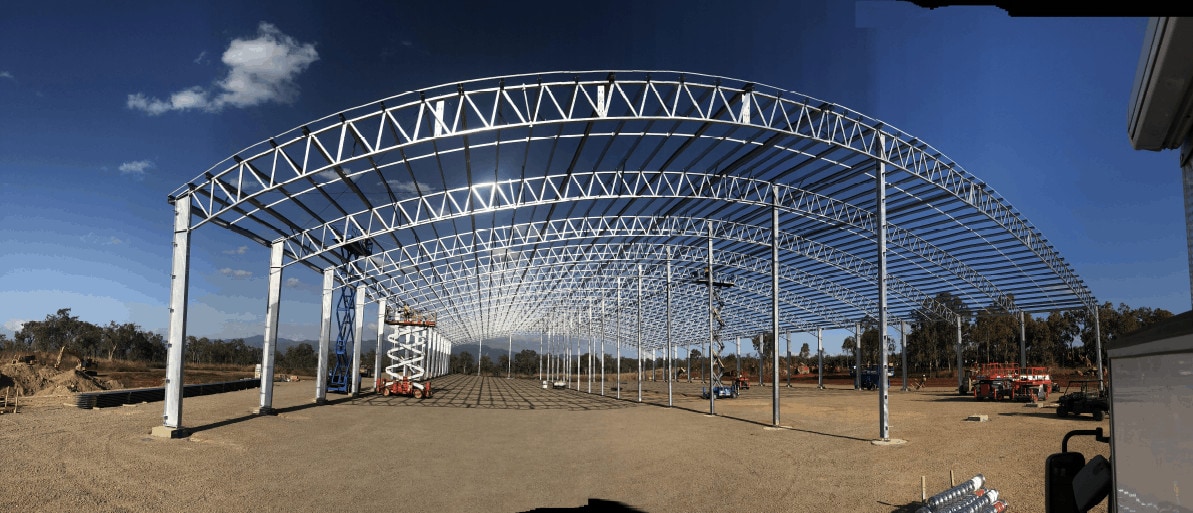

IMAGE DETAILS: Steel fabricated by Entegra Signatures Victoria

Transported to APG from Victoria

Galvanized by APG

Transported to Cairns by APG for delivery to site on the Atherton tablelands